HSS Segmental Saw Blades

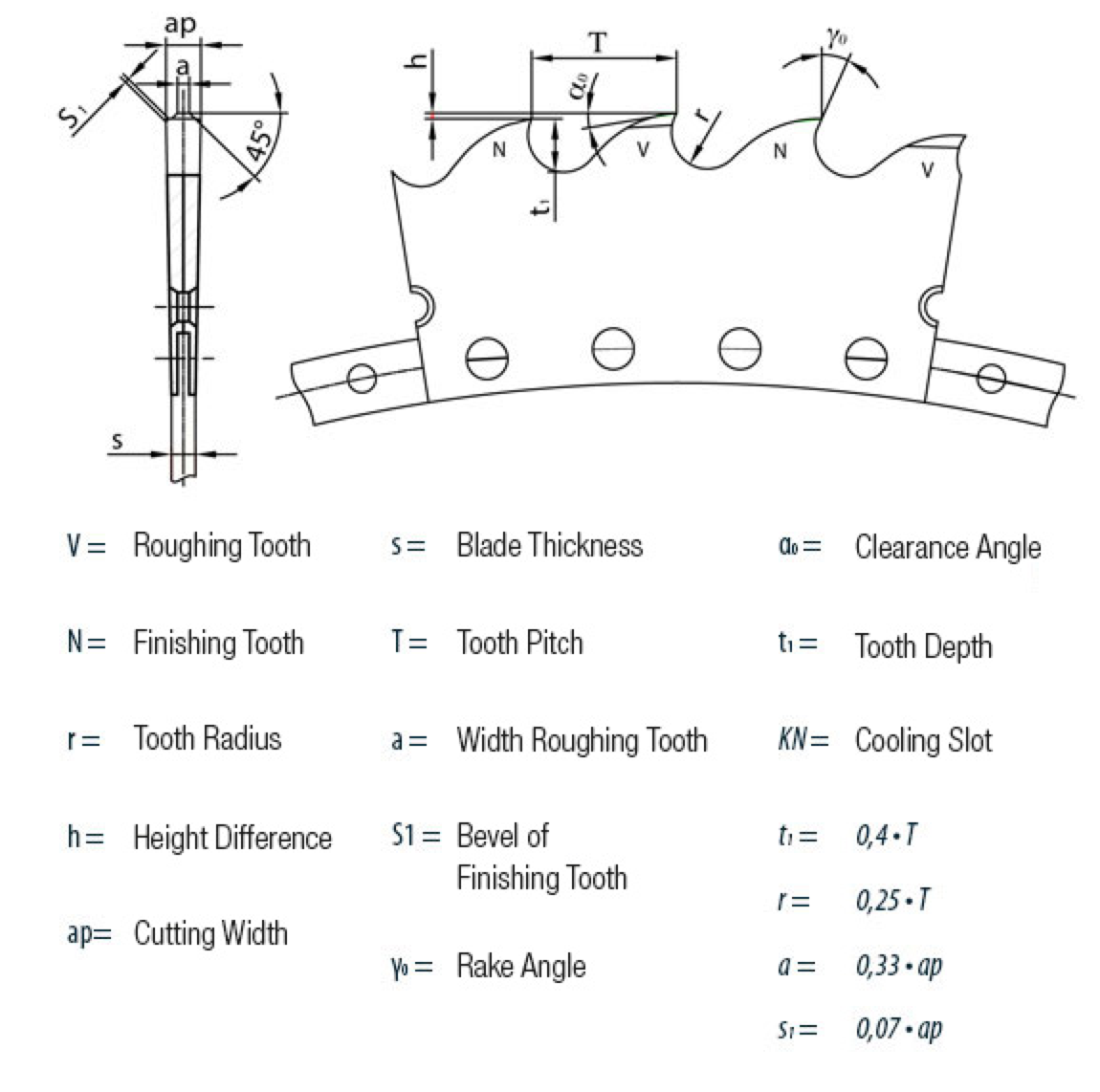

Description

MEW Segmental saw blades are used to cut ferrous and non-ferrous metals, billets, tubes, profiles and bars.

Material: The segments are made of hardened high speed steel of quality DMo5 (M2) or EMo5Co5 (M35). The hardness of approx. 63-65 HRC guarantees optimum protection of wear and high life time of the saw blade. The segments are riveted on high alloyed steel body (tensioned and straightened electronically and have a strength of approx. 1400 N/mm2, size of bore hole = H7).

Capacity: We have manufacturing capacity up to 2100mm.

Common Sizes:

|

Diameter mm |

Kerf width mm |

Body mm |

Number of Segments |

Teeth Number |

Number of teeth per segment |

|||||||

|

Pitch |

2 |

3 |

4 |

5 |

6 |

8 |

10 |

12 |

||||

|

T-mm |

||||||||||||

|

500 |

5 |

3.8 |

18 |

Z |

54 |

72 |

90 |

108 |

144 |

180 |

216 |

|

|

T |

29.1 |

21.8 |

17.5 |

14.5 |

10.9 |

8.7 |

7.3 |

|||||

|

520 |

5.7 |

4 |

18 |

Z |

72 |

90 |

108 |

144 |

180 |

216 |

||

|

T |

22.7 |

18.2 |

15.1 |

11.3 |

9.1 |

7.6 |

||||||

|

560 |

5 |

3.7 |

18 |

Z |

72 |

90 |

108 |

144 |

180 |

216 |

||

|

T |

24.4 |

19.5 |

16.3 |

12.2 |

9.8 |

8.1 |

||||||

|

570 |

5.7 |

4 |

18 |

Z |

72 |

90 |

108 |

144 |

180 |

216 |

||

|

T |

24.9 |

19.9 |

16.6 |

12.4 |

9.9 |

8.3 |

||||||

|

630 |

6 |

4 |

20 |

Z |

60 |

80 |

100 |

120 |

160 |

200 |

||

|

T |

33 |

24.7 |

19.8 |

16.5 |

12.4 |

9.9 |

||||||

|

660 |

6 |

4 |

20 |

Z |

60 |

80 |

100 |

120 |

160 |

200 |

240 |

|

|

T |

34.6 |

25.9 |

20.7 |

17.3 |

13 |

10.4 |

8.6 |

|||||

|

710 |

6 |

4.5 |

24 |

Z |

72 |

96 |

120 |

144 |

192 |

|||

|

T |

31 |

23.2 |

18.6 |

15.5 |

11.6 |

|||||||

|

760 |

6 |

4.5 |

24 |

Z |

72 |

96 |

120 |

144 |

192 |

240 |

||

|

T |

33.2 |

24.9 |

19.9 |

16.6 |

12.4 |

9.9 |

||||||

|

800 |

7 |

5 |

24 |

Z |

72 |

96 |

120 |

144 |

192 |

240 |

||

|

T |

34.9 |

26.2 |

20.9 |

17.5 |

13.1 |

10.5 |

||||||

|

910 |

7 |

5 |

30 |

Z |

60 |

90 |

120 |

150 |

180 |

240 |

||

|

T |

47.6 |

31.8 |

23.8 |

19.1 |

15.9 |

11.9 |

||||||

|

1020 |

8.3 |

6.2 |

30 |

Z |

60 |

90 |

120 |

150 |

180 |

240 |

||

|

T |

53.4 |

35.6 |

26.7 |

21.4 |

17.8 |

13.4 |

||||||

|

1120 |

8.5 |

6.5 |

36 |

Z |

72 |

108 |

144 |

180 |

216 |

|||

|

T |

48.9 |

32.6 |

24.4 |

19.5 |

16.3 |

|||||||

|

1250 |

9 |

7 |

36 |

Z |

72 |

108 |

144 |

180 |

216 |

288 |

||

|

T |

54.5 |

36.4 |

27.3 |

21.8 |

18.2 |

13.6 |

||||||

|

1320 |

9 |

7 |

36 |

Z |

72 |

108 |

144 |

180 |

216 |

288 |

||

|

T |

57.6 |

38.4 |

38.4 |

23 |

19.2 |

14.4 |

||||||

|

1430 |

9.5 |

7 |

36 |

Z |

72 |

108 |

144 |

180 |

216 |

288 |

||

|

T |

62.4 |

41.6 |

31.2 |

25 |

20.8 |

15.6 |

||||||

|

1510 |

10.5 |

8.5 |

36 |

Z |

72 |

108 |

144 |

180 |

216 |

|||

|

T |

65.9 |

43.9 |

32.9 |

26.4 |

22 |

|||||||

|

1610 |

10.5 |

8.5 |

40 |

Z |

80 |

120 |

160 |

200 |

240 |

|||

|

T |

63.2 |

42.1 |

31.6 |

25.3 |

21.1 |

|||||||

|

1870 |

15 |

11 |

42 |

Z |

84 |

126 |

168 |

|||||

|

T |

69.9 |

46.6 |

35 |

|||||||||

Address

Address  Contact

Contact  Phone

Phone