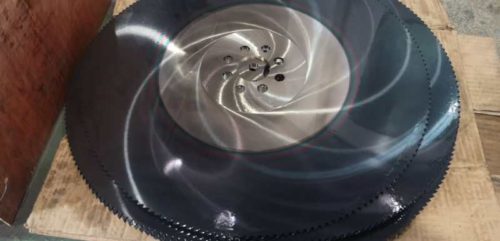

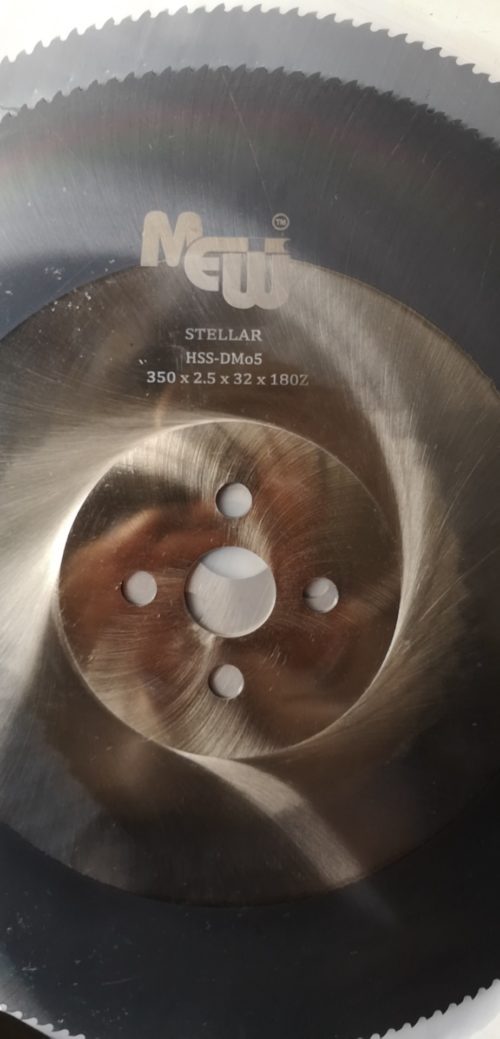

MEW STELLAR

Description

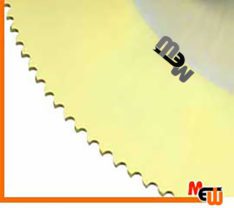

Coating is obtained from the fusion of a titanium/aluminium cathode and is 3 microns thick. It has an oxidation temperature of 800°C resulting in a surface hardness of 3.400 Vickers (HV 0,05). The friction coefficient is 0,45 and allows circular saws to be used with excellent results even in conditions of limited or minimal lubrication and misting. It is particularly suitable for cutting cast iron, stainless steel and all materials that develop considerable heat. read moreDescripción

Coating is obtained from the fusion of a titanium/aluminium cathode and is 3 microns thick. It has an oxidation temperature of 800°C resulting in a surface hardness of 3.400 Vickers (HV 0,05). The friction coefficient is 0,45 and allows circular saws to be used with excellent results even in conditions of limited or minimal lubrication and misting.

It is particularly suitable for cutting cast iron, stainless steel and all materials that develop considerable heat.

Coating Features

| Suitable for cutting | Low-alloy steel 400 – 600 N/mm2, Medium hard alloy steel 700 – 900 N/mm2, Cast iron, Titanium, Nickel (With Misting), Hard steel 950 – 1100 N/mm2, Stainless steel (With Lubrication) |

| Steel friction coefficient(dry) | 0.45 |

| Thickness | 3 |

| Maximum Working Temperature | 560°C |

| Deposition temperature | 490°C |

| Coefficient of thermal expansion (10-6/°K) | 13 |

| Micro-Hardness HV (0,05) | 3400 |

Address

Address  Contact

Contact  Phone

Phone