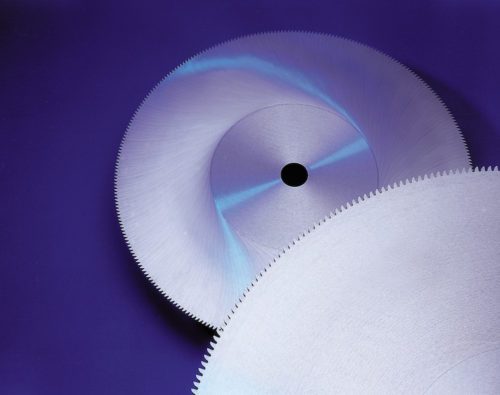

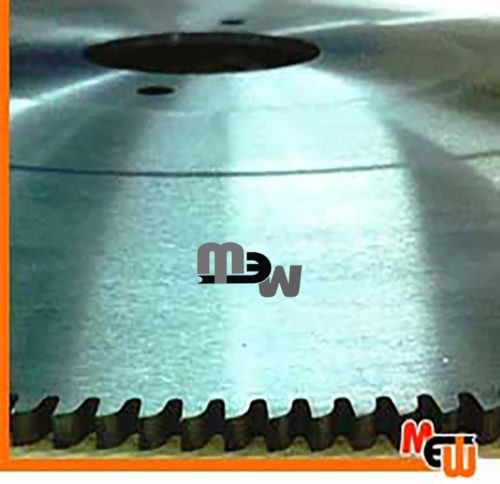

Friction Saw Blades

Description

Our friction saw blades are manufactured in two different materials: chromium vanadium steel (80CrV2 or 1.2235) and tungsten–molybdenum steel (73WcrMoV2 or 1.2604). Our blades are designed for cutting of steel tubes and various sectioned profiles with high peripheral cutting speed under 250°C. read moreDescription

MEW friction saw blades cleanly and reliably cut hollow and structural sections. Longest blade life and best cutting performance are based upon highest quality and numerous particular-processing methods. They are used for friction sawing with stationary and flying sawing plants at welded tube, hollow and structural section rolling mills, for parting gratings, fender walls and many more applications.

Material:

We manufacture friction saw blades in two different materials: Chromium Vanadium Steel (80CrV2 or Din 1.2235) and Tungsten–Molybdenum Steel (73 WCrMoV2 or Din 1.2604).

Tooth forms:

- 0° friction saw tooth for thin wall tubes and structural sections up to approx. 4 mm wall thickness

- 30/30° pendulum shape for thicker walls with approx. 5 mm and above or solid items

- 30/30° pendulum shape with flat land for older machines with low drive capacity,

- Other tooth forms available on request, forged teeth for increased cutting clearance

Standard Sizes

| Diameter (mm) | Thickness/Kerf (mm) | Teeth |

| 300 | 2.5/3.0 | 200 |

| 350 | 2.5 | 200/220 |

| 400 | 2.5/3.0/4.0 | 240/300 |

| 450 | 2.5/3.0/4.0 | 240/300 |

| 500 | 3.0 / 4.0 / 5.0 / 6.0 | 300 |

| 520 |

3.0 / 4.0 / 5.0 / 6.0 |

300 |

| 550 | 3.0 / 4.0 / 5.0 | 300 |

| 600 | 4.0 / 5.0 / 6.0 | 300 |

| 650 | 4.0 / 5.0 / 6.0 | 300 |

| 700 | 4.0 / 5.0 / 6.0/7.0 | 300 |

| 750 | 5.0 / 6.0/7.0 | 300/350/400 |

| 800 | 5.0 / 6.0/7.0/8.0 | 300/350/400 |

| 850 | 6.0/7.0/8.0 | 320/350/380 |

| 900 | 7.0/8.0 | 320/350/380 |

| 1000 | 7.0/8.0/9.0/10.0 | 320/350/380/400/450 |

| 1200 | 8.0/9.0/10.0 | 350/380/400/450 |

| 1500 | 9.0/10.0 | 400/450/470 |

| 1800 | 12.0/14.0 | 400/450/470 |

| 2000 | 14.0/16.0 | 470/524 |

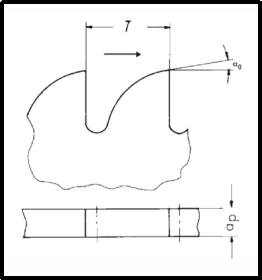

Typical Teeth Geometries

Pendulum saw tooth

γ0 = 0° α0 = 8° suitable for the cold cutting of pipes, profiles and beams

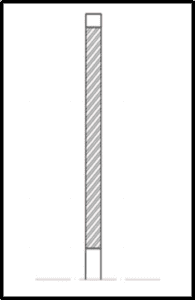

Finish of Side Faces

Flat Ground

Taper Ground

Address

Address  Contact

Contact  Phone

Phone